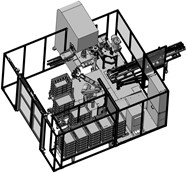

ROBOTIC ASSEMBLY OF FLANGE VALVE MEMBRANE ELEMENTS

The robotic line assembles membrane elements-subassemblies of DN 15, DN20, DN25, DN32, and DN40 flange valves.

At the end of the process in the line, the user prepares the trolleys, which displays the housings on the outside of the line and is placed on the line’s input strip during the process. The semi-finished product is transported through the stages of the line by a robotic arm equipped with quick-change grippers and a vacuum foaming technique.

Automated line:

- the pieces are transferred to the location where the robotic arm takes over by using the band technique,

- glues the housing around the perimeter, and controls the presence of glue,

- reshapes the housings – uses hydraulic compression to create an assembly – the line controls the position of the hydraulic press tool prior to assembly and compression, as well as the final compression force,

- rotates the products 180° to prevent the adhesive from damaging the membrane,

- products are stacked in plastic boxes by matrix,

- loads plastic boxes on trolleys,

- vacuum-loading cardboard partitions between product levels in plastic boxes.