LINE FOR PRIMER INSERTION

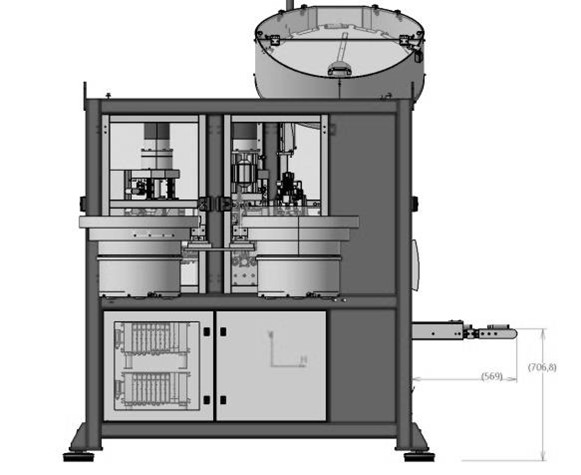

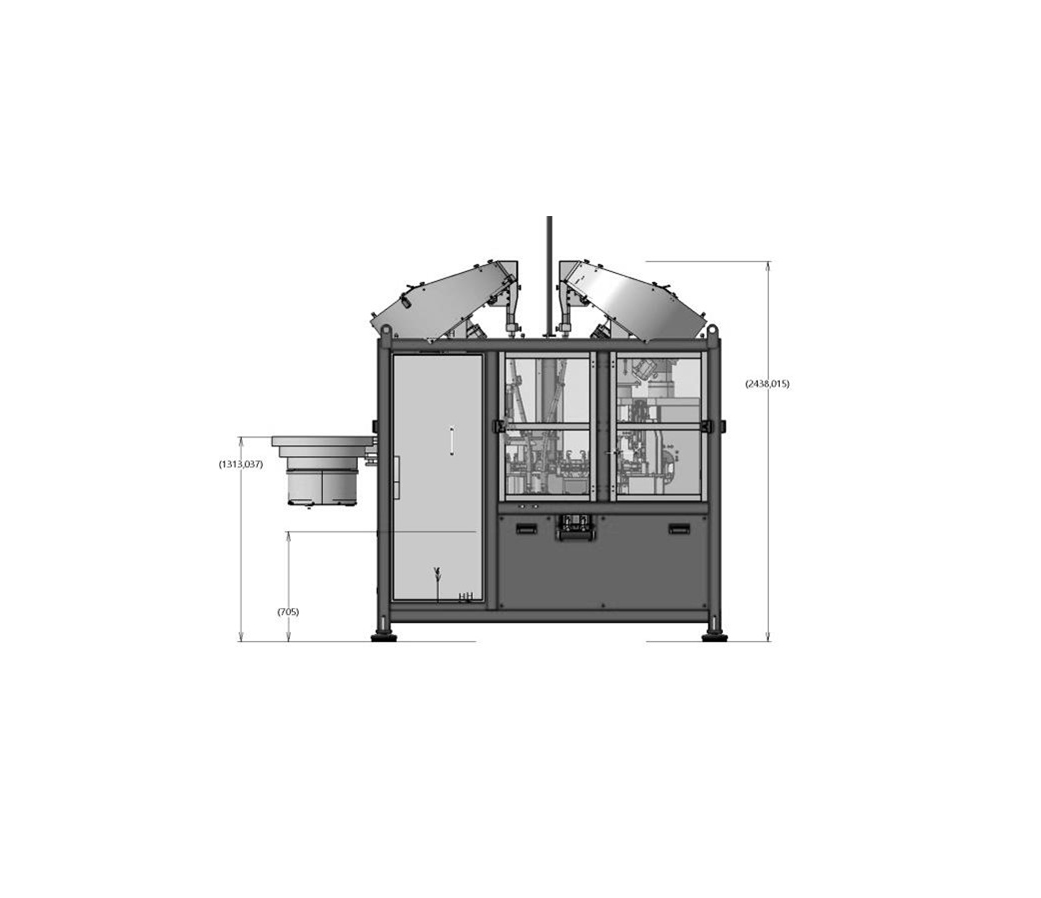

The lines are designed in such a way that the mounting of the primer is carried out in accordance with the technological phases between the stations built in series on the line. Material is transported between stations with a precise index rotating table.

The lines are dedicated and developed individually based on the type of cartridge and the customer’s requirements.

We can provide a 20-minute to 4-hour supply of input material on the line. The input material is supplied by the operator in bulk to the storage tank of the line itself. The product on the line is packaged in bulk in the customer’s desired packaging.

The user interface on the line control panel can be adapted to the customer’s requirements in both language and design.

The line is equipped with all the necessary certificates and standards for machine manufacturing and safety when working with such materials.

We can provide a serial line that is already developed in our range or a custom line based on the customer’s requirements.

The line can also be used to assemble primer on a variety of cartridge sizes.

Example: 12.7×108 and 14.5×114….